Scientists Develop New “Unbreakable Glass”– 3x Stronger, 5x More Fracture-Resistant

By

|

| Shiny nacre of Abalone washed ashore. |

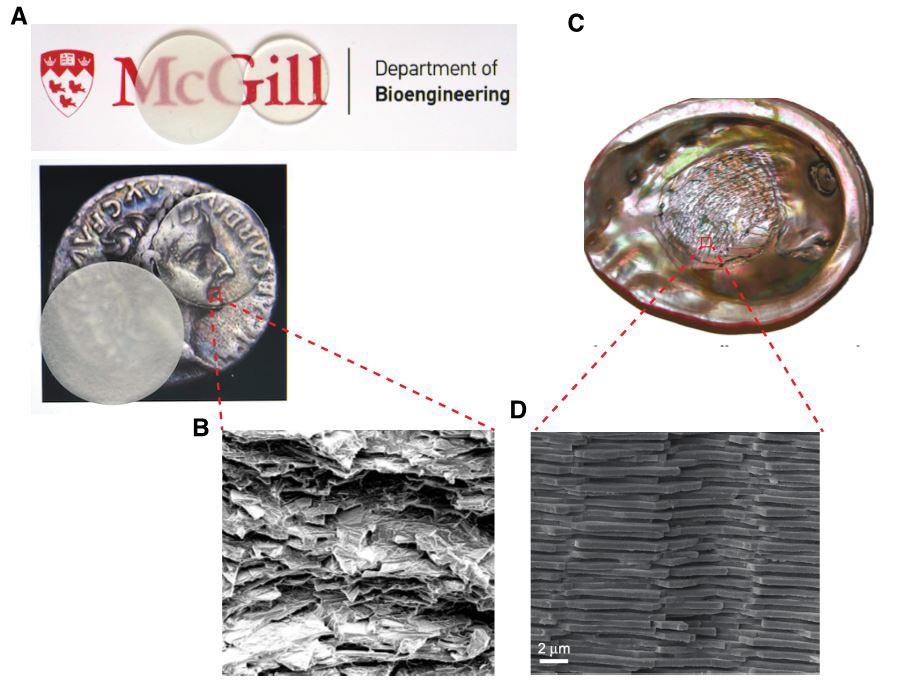

Scientists from McGill University develop stronger and tougher glass, inspired by the inner layer of mollusk shells. Instead of shattering upon impact, the new material has the resiliency of plastic and could be used to improve cell phone screens in the future, among other applications.

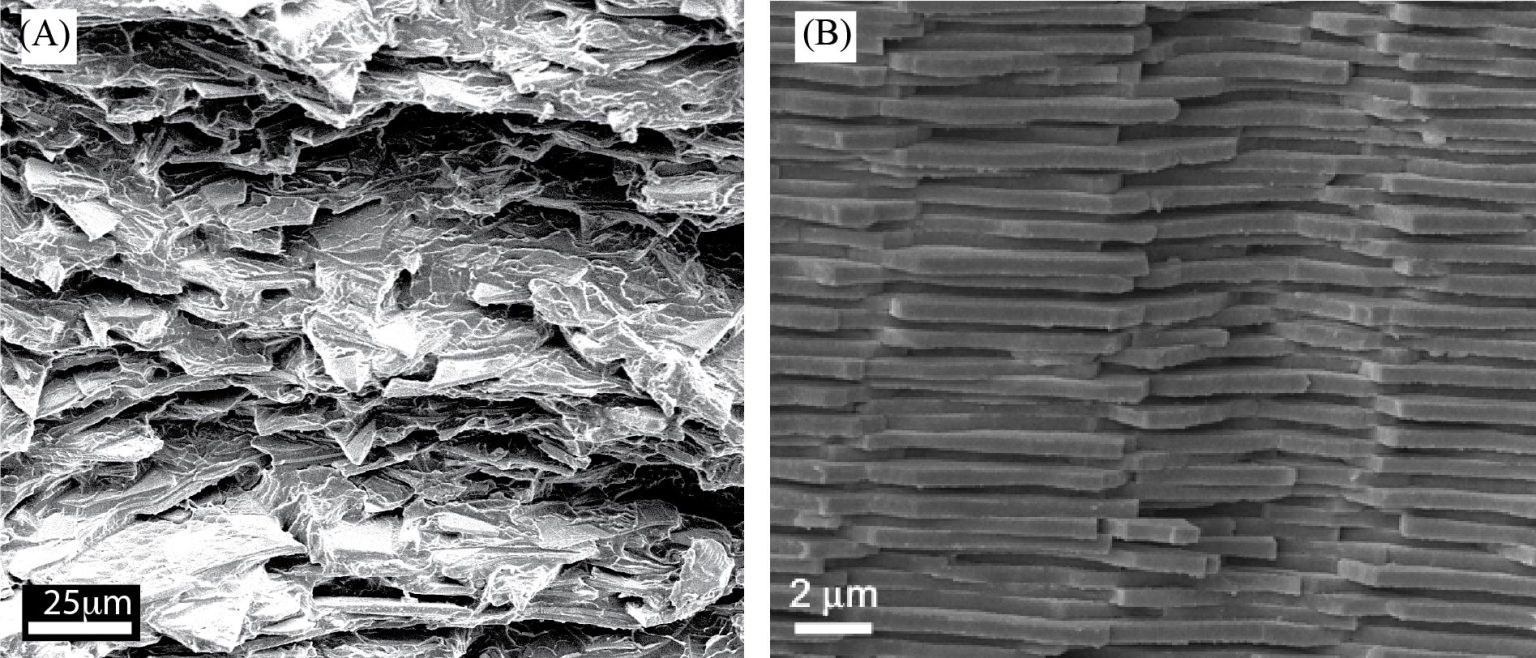

While techniques like tempering and laminating can help reinforce glass, they are costly and no longer work once the surface is damaged. “Until now there were trade-offs between high strength, toughness, and transparency. Our new material is not only three times stronger than the normal glass, but also more than five times more fracture-resistant,” says Allen Ehrlicher, an Associate Professor in the Department of Bioengineering at McGill University.“Amazingly, nacre has the rigidity of a stiff material and durability of a soft material, giving it the best of both worlds,” he explains. “It’s made of stiff pieces of chalk-like matter that are layered with soft proteins that are highly elastic. This structure produces exceptional strength, making it 3000 times tougher than the materials that compose it.”

The scientists took the architecture of nacre and replicated it with layers of glass flakes and acrylic, yielding an exceptionally strong yet opaque material that can be produced easily and inexpensively. They then went a step further to make the composite optically transparent.

“By tuning the refractive index of the acrylic, we made it seamlessly blend with the glass to make a truly transparent composite,” says lead author Ali Amini, a Postdoctoral Researcher at McGill. As next steps, they plan to improve it by incorporating smart technology allowing the glass to change its properties, such as color, mechanics, and conductivity.

After the inventor swore he was the only person who knew how to produce the material, Tiberius had the man executed, fearing that the glass would devalue gold and silver because it might be more valuable.

“When I think about the story of Tiberius, I’m glad that our material innovation leads to publication rather than execution,” says Ehrlicher.

Reference: “Centrifugation and index-matching yields a strong and transparent bioinspired nacreous composite” by Ali Amini, Adele Khavari, Francois Barthelat, and Allen J. Ehrlicher, 10 September 2021, Science. DOI: 10.1126/science.abf0277

(A) Glass composite’s microstructure and (B) Nacre’s microstructure. Credit: Allen Ehrlicher

After the inventor swore he was the only person who knew how to produce the material, Tiberius had the man executed, fearing that the glass would devalue gold and silver because it might be more valuable.

“When I think about the story of Tiberius, I’m glad that our material innovation leads to publication rather than execution,” says Ehrlicher.

Reference: “Centrifugation and index-matching yields a strong and transparent bioinspired nacreous composite” by Ali Amini, Adele Khavari, Francois Barthelat, and Allen J. Ehrlicher, 10 September 2021, Science. DOI: 10.1126/science.abf0277