Maybe PFAS clean-up is possible

National Institute of Environmental Health Sciences (nih.gov)

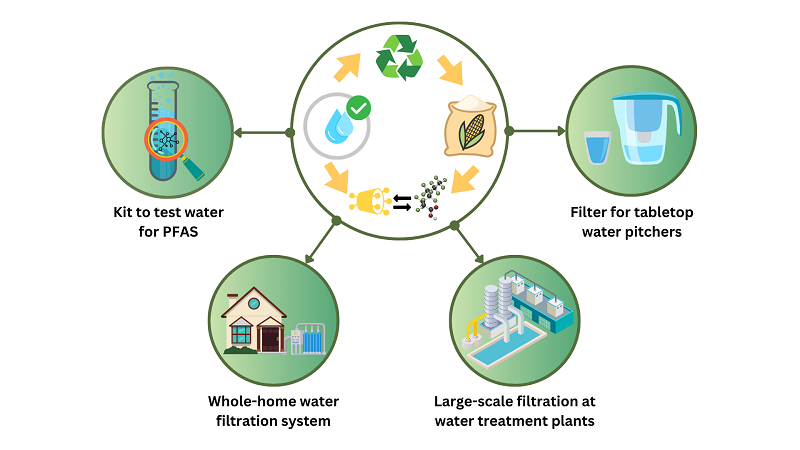

An innovative technology, developed with funding from the NIEHS Superfund Research Program, successfully removes PFAS from water. The technology has been adapted to a variety of applications, including tabletop filters, whole-house water filtration systems, and large-scale cleanup projects.

The Problem

PFAS are a

group of nearly 15,000 human-made chemicals used

for decades in a variety of industrial and consumer products, such as

firefighting foam and food packaging. Due to chemical bonds within the

molecules that are hard to split, PFAS resist natural degradation and can

accumulate in ecosystems and organisms, exposing people through drinking water,

food, and dust. The chemicals have been linked to a variety of health effects,

including changes in immune and liver function, obesity, diabetes, certain

cancers, and lower birth weights.

Current

technologies used to remove contaminants from water, such as activated carbon

and ion exchange treatments, do not work well for some PFAS. These approaches

also have low molecular selectivity — meaning that they are less effective when

other substances besides PFAS are present, which is often the case for

contaminated drinking water systems.

SRP Solutions

Funded by

an SRP small business innovation research grant,

Cyclopure, Inc., developed a sustainable technology to bind and remove PFAS

from drinking water. Their technology is made of cup-shaped cyclodextrins —

sugar molecules bound together in small rings — derived from corn starch. At

less than a nanometer across, the cyclodextrin cup can rapidly bind and trap a

variety of PFAS compounds faster and more efficiently than other filtration

materials.

The

technology can remove all 40 PFAS targeted in the U.S. Environmental Protection

Agency (EPA) PFAS Roadmap and

is certified by the National Sanitation Foundation International (NSF)

as safe for drinking water treatment.

After cyclodextrins trap PFAS molecules, the contaminants can be separated from the cyclodextrins in the laboratory, where the waste is concentrated for safe handling and disposal by destruction technologies without recontamination of the environment. During separation of PFAS waste, the technology undergoes regeneration, allowing reuse of the adsorbent for additional water filtration activities.

In 2022, SRP

provided Cyclopure with additional funding to use their technology in

developing products that detect PFAS and remove them from water. The new grant

allowed the team to pursue PFAS removal solutions for consumer and municipal

applications.

Testing

Water for PFAS

|

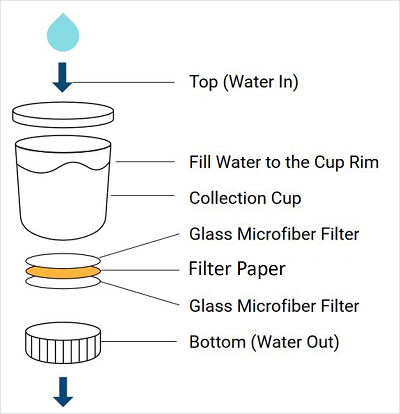

| The water test kit includes a collection cup with a filter disc between two glass microfiber filters. (Image courtesy of Cyclopure) |

Cyclopure developed a kit to test water for PFAS. The kit is listed by NIEHS as a Sensor Technology for the 21st Century.

Their water test kit uses a collection cup with a filter paper made with cyclodextrins that traps PFAS as water flows through it. After collecting a sample, the user returns the kit to the company’s laboratory, where it is analyzed for 55 different PFAS compounds.

According to Cyclopure, their approach is more

cost-effective than currently available technologies and more convenient

because the user does not need to ship water samples. Users are sent a detailed

report about their sample, including concentrations of each PFAS detected and

location-relevant information, such as state drinking water regulations.

The water

test kits have been used to test tap water, rivers, lakes, and streams by

consumers, government agencies, research institutions, and environmental groups

across the U.S. and abroad. The Colorado Department of Public Health and

Environment is using the test kit as part of a program to test the water of

residents who rely on private wells for drinking water. The test kits have also

been used in Japan, the Netherlands, and Bangladesh.

Treating

Home Drinking Water

|

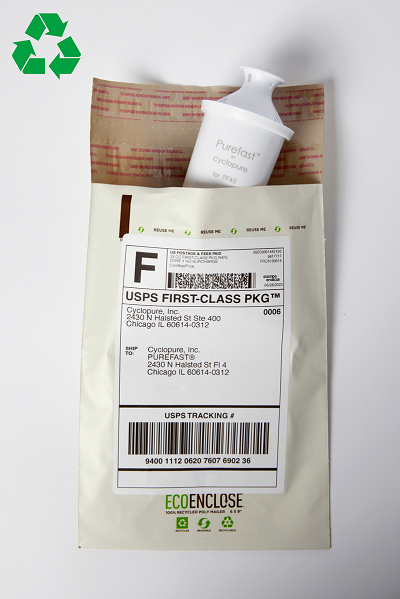

| Each cartridge comes with a prepaid label to return the filter to the lab where the contaminants are safely disposed, and the filters are recycled. (Image courtesy of Cyclopure) |

Families

across the U.S. are using the filter cartridges to prevent PFAS exposures from

drinking water. Municipalities, including communities in Colorado, have

purchased cartridges to provide safe drinking water to households as an interim

solution while they prepare for large-scale water treatment systems.

The company also developed whole-home filter tanks that connect to residential water systems to remove PFAS from tap water throughout the home.

Because not every

consumer can install a whole-home water filtration system, such as those who

rent, an under-the-sink filter that would be more convenient to install and

less costly than the whole-home filters is under development.

Large-Scale

Water Treatment

The

PFAS-removal capacity of cyclodextrins in large-scale applications is

demonstrated through pilot installations across the U.S. These pilots have led

to commercial installations to clean up PFAS-contaminated water in:

- Municipal drinking water plants

- Landfills

- Groundwater

- Industrial wastewater

In 2024, the Massachusetts Department of Environmental Protection approved the use of the company’s cyclodextrins to remove PFAS from drinking water systems throughout the state. This approval followed 12 months of pilot testing in Newburyport and Lynnfield, Massachusetts, that successfully demonstrated reduction of PFAS in water to nondetectable levels throughout the study period.

Additional pilot testing is ongoing at municipal drinking water plants in Maryland, Alabama, and Nevada, with additional installations slated for New Hampshire, Pennsylvania, Georgia, and North Carolina. The company will install a full-scale treatment system in Alaska at the beginning of August 2024.

Also in

2024, Cyclopure began a pilot study to treat contaminated groundwater with PFAS

at the Willow Grove Naval Air Station in

Pennsylvania. The team installed a full-scale treatment system at another

Department of Defense site in the state, the Biddle Air National Guard Base.

The company

has been working with landfill operators in Michigan and Pennsylvania to

demonstrate removal of PFAS from landfill leachate. Landfill leachate forms

when rainwater filters through wastes placed in a landfill and often contains

high concentrations of PFAS leaching from different household goods.

The

technology is also being used to remove PFAS from industrial waste streams,

with full-scale treatment systems operating at a metal plating plant and

petroleum facility.

Lowering

Treatment Costs

In a

year-long pilot test to remove PFAS from wastewater at a metal plating plant in

Michigan, Cyclopure demonstrated that their technology requires less material

to clean up water than currently used water treatment methods. Compared to the

plant’s approach that used 180,000 pounds of activated carbon, Cyclopure was

able to accomplish similar performance using 21,000 pounds of cyclodextrins.

“We hope that our technology can help lower the cost of water treatment efforts and boost sustainability, preventing PFAS exposures and ultimately protecting human health,” said Cyclopure chief executive officer Frank Cassou.